Steel Light Poles are robust and durable, designed to support various lighting fixtures. They offer excellent resistance to weather and corrosion, ensuring long-term performance. Ideal for streets, parking lots, and public spaces, they enhance safety and visibility.

Light pole production process

Steel plate leveling---rod winding---welding--- grinding and straightening--- hot galvanizing---grinding and straightening---plastic spraying and packaging.

The process of all bars is like this. Let's take the street lamp bar as an example to introduce it emphatically.

Delivery

Detailed introduction of production process flow of bar

1. Cutting and shearing All materials with a thickness of ≦12mm are cut by numerical control plasma, and those with a thickness of > 12mm are cut by numerical control flame or plate shearing. CNC plasma cutting tolerance ±2mm , CNC flame cutting or shearing tolerance of 3 mm.. 2. Bending Bending is a key process in the production of light poles. The quality of light poles is directly affected by bending and cannot be repaired after bending.

The specific attention is as follows:

2.1 Before bending: firstly, remove the slag from the sheet to ensure that the mold is not crushed by the slag during bending;

2.2 Check the length, width and straightness of the sheet metal, and the straightness shall be ≤ 1/1000. If the straightness meets the requirements, make corrections, especially for polygonal rods. ;

2.3 Increase the bending depth of the bending machine to determine the placement position of the sheet metal;

2.4 Draw a line on the sheet correctly, with an error of 1 mm; 2.5 correct alignment and correct bending, so that the pipe joint can meet the requirements, and at the same time, the two sides are not more than 5mm high and low.

3. Welding All main materials ≦6mm are welded by automatic gas shielded welding, and all flanges and ribs are welded by manual gas shielded welding when the thickness is greater than 6mm. Weld saturation Full smoothness, no defects such as air holes, virtual welding, missing welding and undercut.

4. repair and polish Repair grinding is to repair the defects at both ends of the steel pipe after automatic welding. Repair personnel should check one by one, and repair the defective parts. After the repair welding is completed, , and then grinding, grinding joint and automatic welding seam are basically the same.

5. Plastic surgery The shaping process includes the straightening of the lamp pole and the dimensions of the whole circle and polygon diagonal at both ends of the blank pole. The general tolerance is < 2mm. The straightness error of blank rod shall not exceed ≤ ±1.5/1000。

6. welding flange The key to spot welding the bottom flange and rib plate is to ensure that the bottom flange is vertical to the straight center line of the lamp and the rib plate is vertical to the bottom flange. Welding requirements refer to the national standard welding process. Ensure the welding quality. The welding seam should be beautiful, free of air holes and slag inclusion.

7. Open the door In the working process of this process, we must first look at the drawings to determine the direction of the door, and then locate it according to the size of the drawings. Dimensions include: up and down, left and right, and door frame size. Size, be careful when plasma cutting, ensure that the cutting seam is straight, and at the same time, the cut door panel is coded.

8. Weld door bars, electrical bars and lock seats When welding the door strip, the 20mm wide door strip should be put down at a position of 8-10mm, especially when spot welding, the door strip should be close to the lamp post, and the welding should be firm. Welding bar and lock seat mainly The position is determined according to the drawing, and the lock seat is welded in the middle of the door, with an error of ≤±2mm, keeping the top level and not exceeding the lamp post.

9. Galvanizing Galvanizing directly affects the quality of lamp poles. Galvanizing is required to be carried out according to national standards. After plating, the surface is smooth without color difference, and there can be no sagging or serious sagging of lamps. The rod must be repainted. 10. Plastic spraying The purpose of plastic spraying is to be beautiful, and the other is to prevent corrosion;

10.1 Polishing: Smooth the surface of galvanized pole with polishing grinding wheel to ensure smooth and flat surface of lamp pole.

10.2 Straightening: Straighten the polished lamp post and reshape the mouth shape. The straightness of the lamp post must reach 1/1000, and the caliber requirements are: small post ≤ 1 mm; High pole ≤±2mm .

10.3 door panels

10.3.1 All door panels shall be treated after zinc plating, including zinc hanging, zinc leakage and zinc storage in lock holes.

10.3.2 When drilling screw holes, the electric drill must be vertical to the door panel, the clearance around the door panel should be equal, and the door panel should be smooth.

10.3.3 After the screws are fixed, the door panel must not be loose to prevent it from falling off during transportation.

10.3.4 plastic powder spraying: put the lamp post with the door installed into the spraying room, spray the plastic powder color according to the requirements of the production plan, and then enter the drying room. The temperature and heat preservation time of the drying room must be Strictly follow the requirements of plastic powder to ensure the quality requirements such as adhesion and smoothness of plastic powder.

11.the factory inspection The factory inspection shall be conducted by the company's quality inspector, who shall conduct inspection item by item according to the lamp post inspection items, and shall make records and file them at the same time, which can be issued only after the quality inspector signs them.

Rod is the carrier of all equipment, and it is divided into:

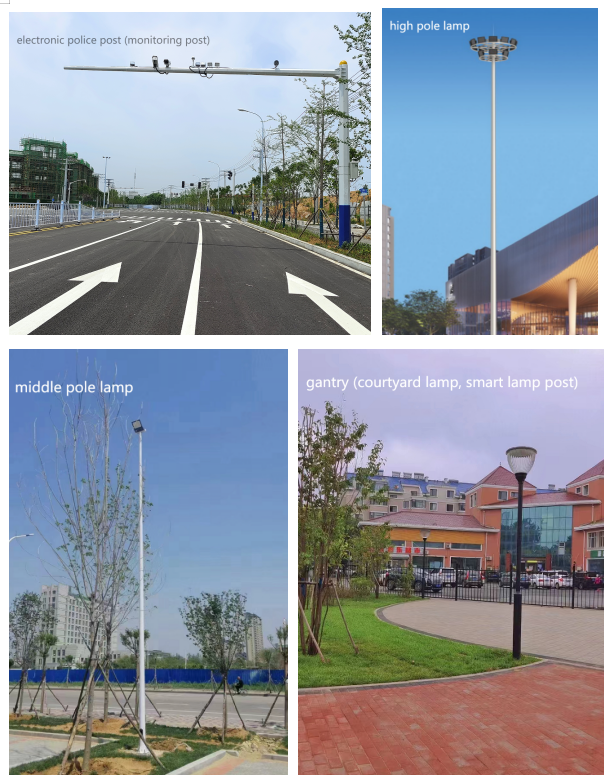

LED lamp post, solar lamp post, traffic lamp post, pedestrian lamp post, electronic police post (monitoring post), high pole lamp, middle pole lamp, gantry (courtyard lamp, smart lamp post) and so on.

Figures

Name of parts:

Main pole, flange, stiffener, cross arm, embedded/ground cage, mounting bracket.